SBM in the Heidelberg quarry in Nußloch

Since the early 1960s, the Nußloch quarry has supplied limestone and marl for the Leimen cement plant. However, with the discontinuation of clinker production at the Heidelberg Materials site at the beginning of 2023, the extraction of the high-quality rock also came to an end. Previously, the rock was pre-crushed (0/280 mm) by a roller crusher and transported via a 2.0-km land conveyor belt to intermediate silos. From there, it was transported via a 5-km-long material cableway to the cement plant. Following the restructuring of the Heidelberg Materials Mineralik DE raw materials division in 2023, a new gravel plant was built in the quarry to produce high-quality concrete aggregates and road construction materials.

The existing technical equipment required major investments in new processing technology. During the tendering process, which began in 2022, it quickly became apparent that the site’s clear quality-oriented positioning in the regional market, and Heidelberg Materials’ long-standing commitment to sustainability in Nußloch in particular, presented real challenges for the participating planners and suppliers. In mid-2023, the contract for the complete processing technology was awarded to Austrian company SBM Mineral Processing. This includes primary, secondary and tertiary crushing stages, each with efficient dust extraction, as well as wet processing of all concrete aggregates and road construction gravel. The customer also required the plant concept to include sludge and wastewater treatment.

Six months after the plans were approved and the old plant dismantled, the seven-month installation of the plant components began in April 2024. Following completion of the electrical installation, the plant was commissioned in March this year, representing a total lead time of just under 20 months from order placement. The customer is highly satisfied: “The cooperation with SBM was absolutely convincing throughout the entire planning and tendering process as well as the construction phase,” says Nicki Beyerle, authorised signatory and Head of Production and Technology South at Heidelberg Materials Mineralik. “Our technical specifications were fully met. The project team also actively supported us in achieving our goal of producing high-quality end products based on our raw materials, ensuring our successful market entry as a new regional supplier.”

Wide product range

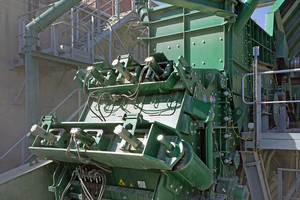

The new plant makes use of the existing structures and the ample open spaces around the existing machine hall. The RHS 13/16/4 horizontal impact crusher has been placed on the adapted foundation of the previous primary crusher and is equipped with a 60 m³ feeder and an efficient VARK 14/30-2 double-deck primary screen. The primary screen separates the crushed material into 80/800 and 30/80 bypass fractions, as well as a 0/32 pre-screening fraction. The latter is stocked as unqualified road construction materials or can be added to rock crushed to 0/200, if required. The same applies to the defined filler fractions captured by the dedusting system in the primary stage. The primary crusher is fed by large wheel loaders from the intermediate stockpile or directly by 50-tonne trucks and achieves a feed capacity of 350 – 400 t/h.

Via a fully enclosed, 130-m-long, land and incline conveyor belt with a 90° transfer station, the crushed material reaches a 200 m³ buffer silo in the gravel plant on a higher level with secondary and tertiary crushers and a total of four production screening stages. The secondary crusher is a reversible horizontal impact crusher (SMR 13/13/4). Designed specifically for the highly efficient production of crushed sand and high-quality chippings, the crusher impresses with its large defined fine grain fraction, the very good cubicity of its end products, and its low operating and wear costs. Placed directly below the buffer silo, the SMR 13/13/4 produces an intermediate grain size of 0/50 with an hourly output of up to 280 t. Like the downstream tertiary crusher, it is connected to a highly efficient dust extraction system with a loading silo.

Monitored by belt weighers, the intermediate grain 0/50 is fed to the KS 24/70/2 double-deck washing screen. There, it is separated into the 8/50 fraction, the final grain of 2/8 and the fine fraction of 0/2 for further processing. The latter passes through a CABrex Compact plant from the Austrian CAB Group, which has a hydrocyclone located directly below the washing screen for dewatering. This produces high-quality 0/2 mm sand, or 0/1 mm if required. Process water from the washing screen and dewatering is sent to the plant’s own wastewater treatment system with an attached chamber filter press for recycling.

The washed intermediate grain size (8/50) passes through two SBM production screening machines (KQ 15/740/2.5 with 2.5 decks and KQ 15/40/1 with one deck), which produce the remaining final grain sizes (8/16, 16/22, 22/32 and 32/45). Any excess grain sizes or end products can be recirculated via a conveyor belt to the SMR 10/5/4 tertiary crusher (0/50; up to 80 t/h) for the production of smaller fractions. The smaller SBM “sand mill” produces high-quality sand and gravel while ensuring low operating costs, making it a genuine alternative to two-stage tertiary crushing combinations consisting of cone or gyratory crushers with vertical impact crushers downstream.

With a production capacity of around 280 t/h, all end products are stored on stockpiles with a total volume of around 10 000 t in the immediate vicinity of the plant. From there, they are loaded onto company or customer trucks.

Good prospects

Thanks mainly to the impressive quality of its internally and externally monitored end products, the management at Heidelberg Materials Mineralik DE is already planning for an annual production volume of 400 000 t in the medium term, with concrete aggregates accounting for 60 % and road construction materials for 40 %. Personnel costs are kept to a minimum thanks to largely automated processes: seven employees per shift are required for the entire operation, including quarrying. The plant is also designed for cross-seasonal operation – production is possible down to -3°C without the need for complex enclosure.

In terms of sustainability, the plant also meets the high standards of the Nußloch site with its award-winning restoration measures, programmes for the preservation and reintroduction of endangered species, and environmental projects for interested citizens. Shortly after commissioning, the new plant was awarded the Concrete Sustainability Council (CSC) Gold Certificate for sustainability.