The collision mechanics of impact and percussion comminution – Part 1

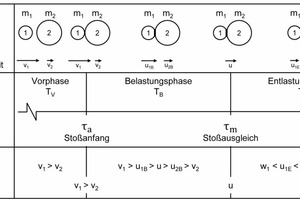

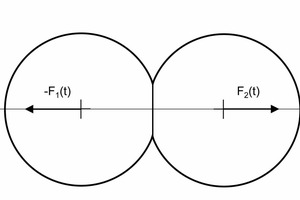

In numerous machines, comminution of primary and secondary raw materials is based on the physical effect of collision. This effect is realized by means of the active principles of impact and percussion. These active principles effect four types of collision either between the raw material particles or with machine components: elastic-plastic, rebounding, penetrating and energy-releasing collisions.

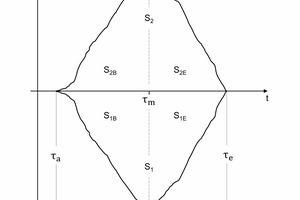

Widening of the theory of restitution to the theory of collision enables its formulation in physical terms. For this purpose, the coefficient of restitution is extended and termed the coefficient of collision. The value range then extends from -1 to ∞. Here the coefficient of collision from -1 to 0 characterizes the penetrating collision, from 0 to 1 the elastic-plastic and rebounding collisions and from 1 to ∞ the energy-releasing collision. Comminution is effected in all collision types apart from in elastic-plastic collisions.

1 Introduction

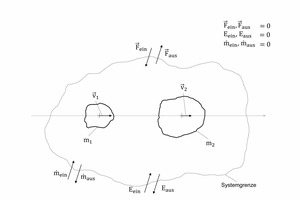

Primary and secondary materials are often comminuted in machines that utilize the physical effect of collision. The raw material particles are comminuted either as a result of impact or percussion with the work surfaces, the moving or non moving machine walls or between the particles themselves. In the case of impact loading, moving particles impact a non-moved wall (e.g. in impact crushers with centrifugal rotors, VSIC), moving walls impact particles (e.g. in impact crushers with rotor beaters, HSIC) or moving particles impact each other (e.g. in jet mills). In percussion...