Flender One gearbox platform expansion

16.02.2026"Unlimit your gearbox." This tagline has guided Flender's development of its revolutionary Flender One platform since its launch in 2022. Flender announced the next major milestone: the platform now covers all major industrial gearbox applications while solving what was previously considered an impossible challenge in industrial manufacturing – combining complete customization with the speed and economics of series production. This is powered by Flender's proven end-to-end digital chain that continues to set standards in mechanical engineering digitalization.

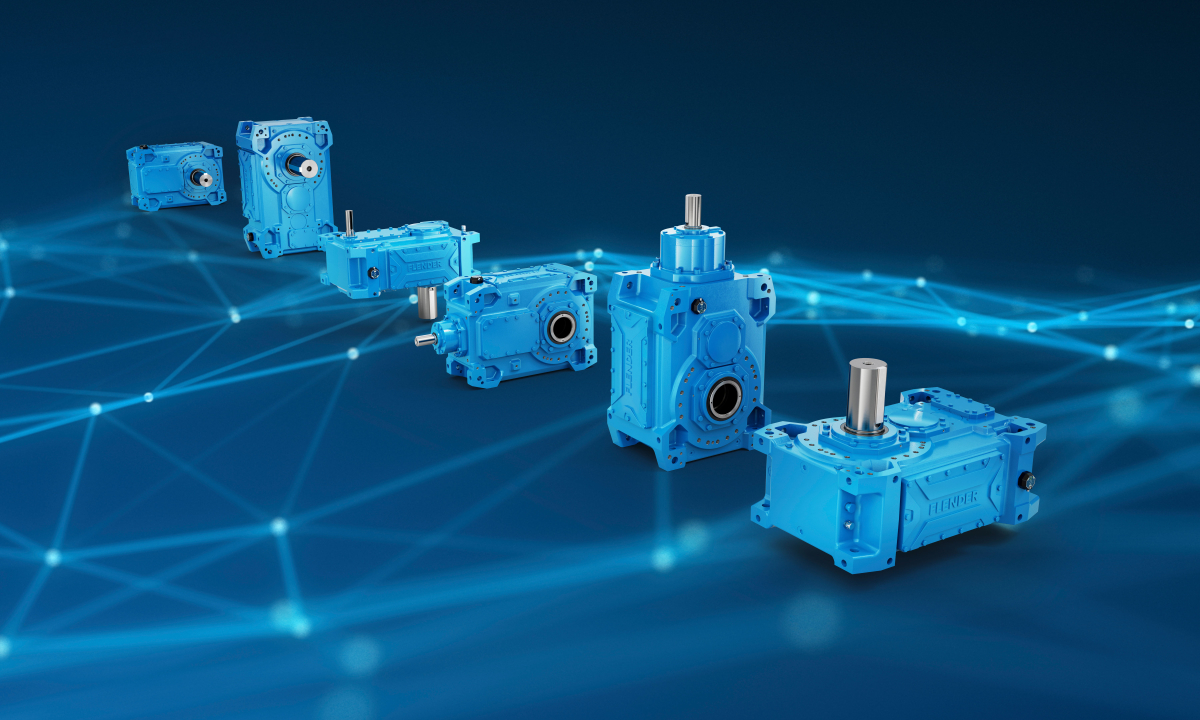

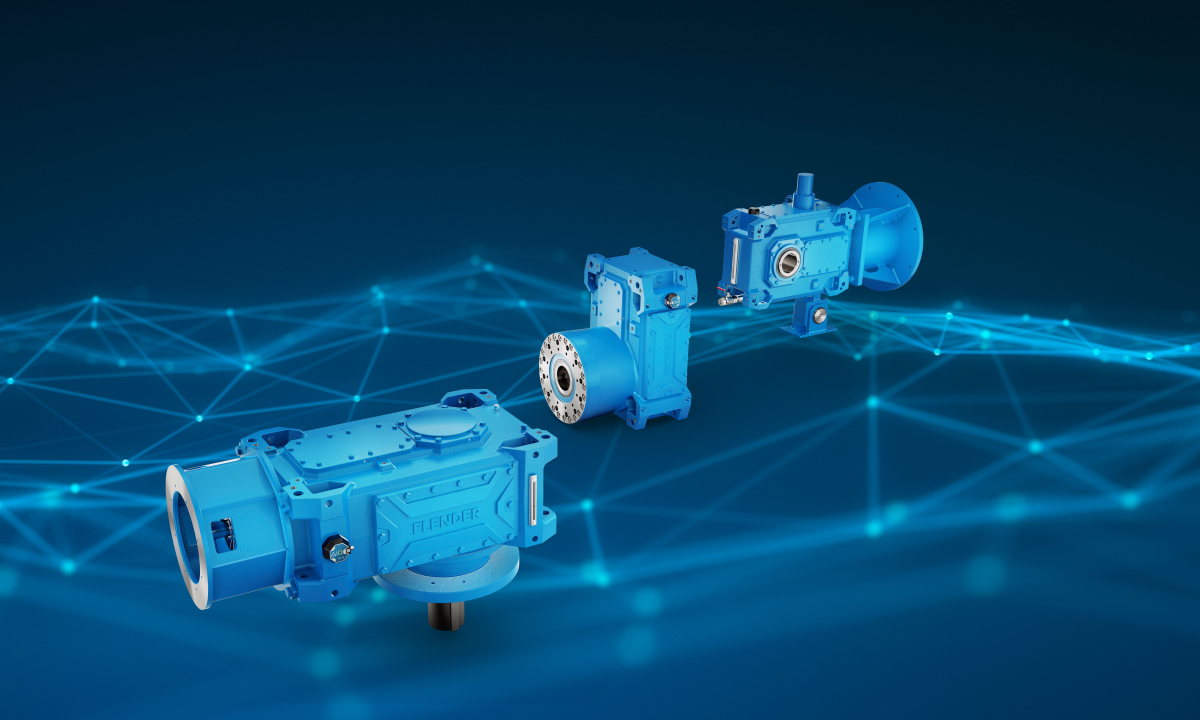

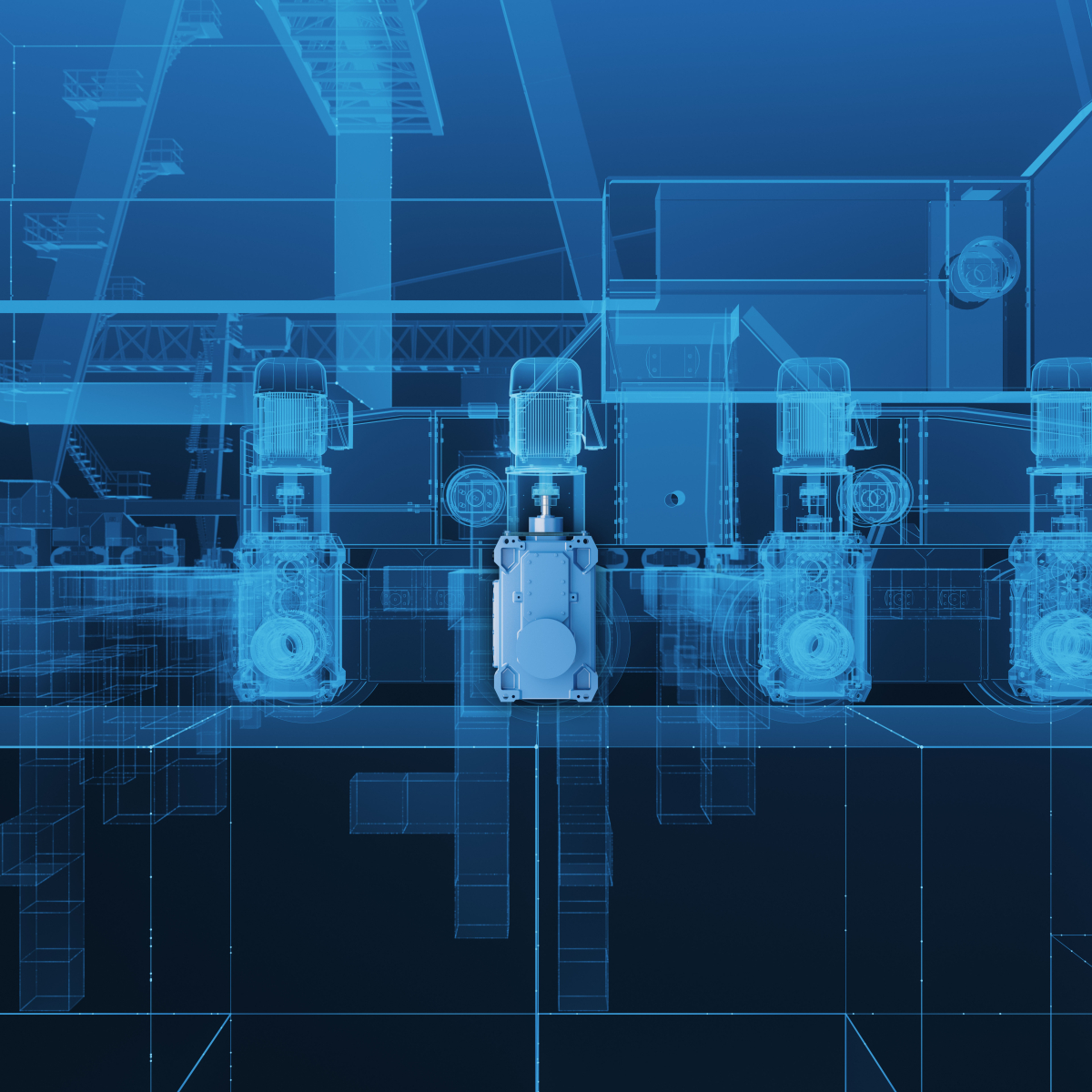

The new FLENDER ONE variants in February 2026: From two-stage to four-stage gearboxes, available in helical and bevel-helical configurations for highest mounting flexibility up to a power of 4807 kW / torque to 153 000 Nm

The new FLENDER ONE variants in February 2026: From two-stage to four-stage gearboxes, available in helical and bevel-helical configurations for highest mounting flexibility up to a power of 4807 kW / torque to 153 000 Nm

© Flender

With the latest addition of a universal housing concept, Flender One can now be configured for vertical, horizontal, or any mounting orientation. This advancement opens up entirely new applications that were previously impossible to serve with the platform, including agitators and mixers in chemical, food, and pharmaceutical industries, water screw pumps and aerators in water and wastewater treatment, separators, and travel drives in material handling and logistics.

Combined with existing coverage for pumps, paper machines, conveyor systems, overhead cranes, and dozens of other applications, Flender One now addresses virtually every major industrial gearbox requirement. What makes this achievement remarkable is not just the breadth of applications, but that each gearbox is fully individualized to exact customer specifications while maintaining the delivery speed and cost efficiency of a standard catalog product.

Versatility demonstrated: Flender One gearboxes shown with various mounting options and application-specific add-ons

Versatility demonstrated: Flender One gearboxes shown with various mounting options and application-specific add-ons

© Flender

Engineered in minutes, not weeks

At the heart of Flender One's success is its online configurator at flender.com/one. The system fundamentally changes how customers specify industrial gearboxes. Traditional selection processes require extensive technical knowledge and weeks of engineering time. Flender One customers simply enter three parameters: application, power requirement, and rotation speed.

"We've eliminated the traditional trade-off between customization and speed," explains Dr. Jan Reimann, Project Lead Flender One. "Customers no longer need to choose between a standard catalog product that doesn't quite fit or waiting weeks for a custom solution. They tell us what they want to achieve, and our intelligent system designs the perfect solution within minutes, delivering complete 3D CAD models, technical drawings, and comprehensive documentation. A digital twin of the drive is immediately available for the development of the plant."

The configurator draws on a digital engineer with more than 125 years of Flender application expertise, automatically dimensioning each gearbox precisely for its intended use. This approach eliminates the chronic over-dimensioning that industry data shows wastes up to 50% of materials in traditional industrial gearboxes, while still ensuring optimal performance and reliability for the specific application.

Flender One in mixer

Flender One in mixer

© Flender

Individual. Efficient. Smart.

Like every Flender One, the new release delivers on three fundamental pillars:

- Individual: Each gearbox is custom-engineered to exact customer specifications through a fully digital process. With over one million possible configurations across the platform, customers receive precisely what they need for their specific application. Every Flender One maintains identical footprint and connection dimensions within its size class, enabling straightforward 1:1 retrofit of existing Flender industrial gearboxes without modification to surrounding equipment.

- Efficient: Flender One's optimized design reduces power dissipation by up to 50 % compared to predecessor models. The 30 % higher thermal capacity often eliminates the need for external cooling systems. The online configuration and automated manufacturing process reduces project planning time by up to 25 %, with faster delivery and lower operating costs throughout the gearbox lifecycle. Precise dimensioning ensures customers pay only for the capacity they need, not the safety margins built into standard catalog products.

- Smart: Every Flender One includes Flender AIQ gearbox intelligence as standard. The integrated sensor technology monitors critical parameters in real-time, enabling predictive maintenance that reduces unplanned downtime by up to 70 % and cuts maintenance costs by up to 40 % through data-driven service intervals. The AIQ solution includes a comprehensive cloud-based analytics software suite with every gearbox.

Flender One in water screw pump

Flender One in water screw pump

© Flender

Solving the industrial trilemma

The Flender One platform demonstrates how complete digitalization can transform manufacturing. The underlying FIRE (Flender Intelligent Rule Engine) platform enables seamless end-to-end digitization from customer configuration through automated manufacturing to operational monitoring. This digital backbone allows Flender to offer what was previously impossible: universal application coverage, complete individualization, and series production efficiency simultaneously.

"Flender One proves that digital transformation unlocks entirely new business models," states Andreas Evertz, CEO of Flender. "We're offering highly individualized products with the speed and cost efficiency of series production – something previously thought impossible in manufacturing. This approach creates a competitive advantage and serves as a blueprint for industrial transformation."

"We've achieved true customization at scale, serving 100 % of major industrial applications with individually tailored gearboxes," says Aleksandra Meissner, President of Industrial Gears at Flender. "But we're not stopping here. Flender One continues to evolve, and we're excited about the innovations still to come."

Flender One in travel drive applications

Flender One in travel drive applications

© Flender

Immediate availability and ordering

The new Flender One variants are available for immediate ordering through the online configurator at flender.com/one. Registered customers can configure and submit inquiries directly through the platform. All customers are welcome to contact their Flender sales representative or use the contact form at flender.com/one for personalized support.

Flender will continue expanding the platform with larger size ranges and ultimately achieve the industry milestone of fully tailor-made industrial gearboxes manufactured with series production efficiency.