HD Hyundai opens new smart factory in Ulsan

22.07.2025HD Hyundai Construction Equipment has invested € 131 million in the development of a smart factory at its Ulsan Campus in South Korea. The 4710 m2 campus is a single cohesive facility, with automated product flow and advanced quality control, has seen the modernised factory increase production capacity by 56 %.

© HD Hyundai

© HD Hyundai

The company has been working on the Advancement Project since 2023, expanding and reorganising production lines, constructing a new quality assurance centre and a new receiving building, developing an updated office structure and transforming the plant into a smart facility. Production and logistics have been streamlined under an integrated factory system, while a real-time product tracking system has been introduced, to optimise workflow and overall efficiency.

© HD Hyundai

© HD Hyundai

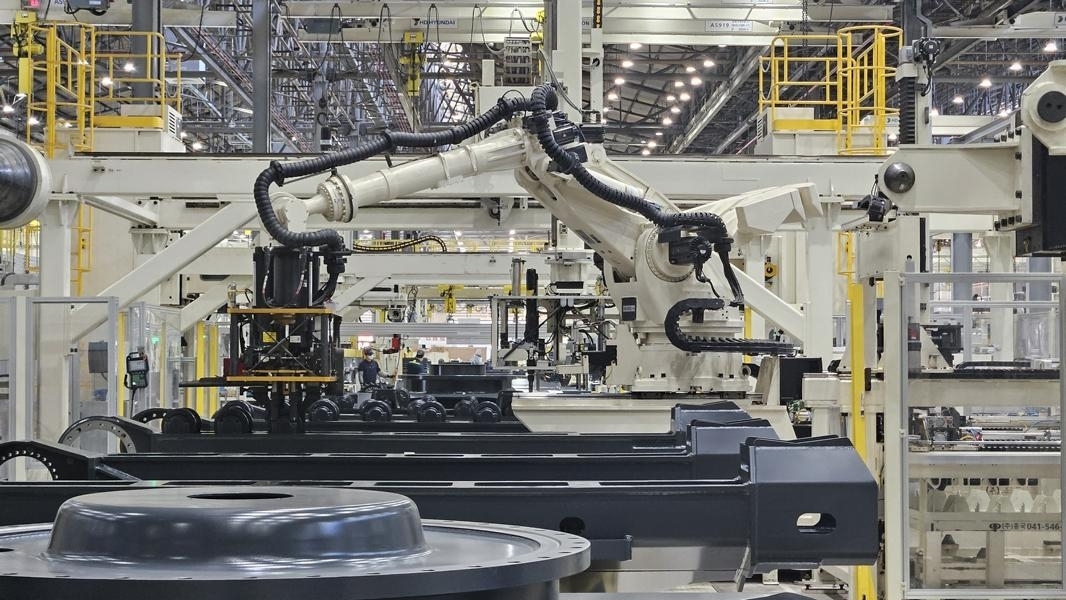

Welding robots have been installed in the fabrication facility, with vision sensors on the body welding production line, enhancing productivity and quality consistency. Unmanned transport vehicles (AGVs) and AI-based quality inspection systems in the assembly line further increase automation. This has resulted in a labour productivity improvement of more than 20%, while the time required to complete a machine has decreased by up to 35 %.

© HD Hyundai

© HD Hyundai

The Ulsan facility, which builds medium to large excavators and wheel loaders, will see production capacity rise by 56 %, from 9600 units a year to up to 15 000 machines annually, allowing the company to meet the growing demands from customers worldwide. The smart facility will act as a ‘Mother Plant’ with direct connections to HD Hyundai’s major overseas production plants and customisation centres in Europe and the United States.

“The new factory, transformed with a smart and safe production system, aims to become the world’s leading production hub, integrating advanced technology and environmental sustainability,” says Kwon Oh-gap, HD Hyundai chairman.

© HD Hyundai

© HD Hyundai

The site has already delivered its first machines, including a 40-tonne Next Generation crawler excavator that was launched to the market at the recent Bauma exhibition in Munich. The site has also provided a 125-tonne class excavator and 35-tonne large wheel loaders to dealers around the world.

“The Ulsan Campus has been transformed into a smart factory, significantly improving its quality competitiveness,” adds Choi Cheol-gon, HD Hyundai CEO. “We are dedicated to providing top-tier products, that will lead the construction machinery sector, including our Next Generation models.”