Smarter maintenance starts here: the new i-STEP Operator

28.11.2025In many companies, machine monitoring is not yet based on facts, but rather on empirical values – an approach that is becoming increasingly unreliable as tasks become more complex and staff shortages increase. At the same time, smooth, safe, and cost-efficient operation must be ensured, even in economically challenging times. Permanent condition monitoring is therefore more important than ever before. This is precisely where the new i-STEP Operator proves indispensable. The innovative tool from IFE Material Handling enables plant managers to monitor machines based on facts and helps them to make their daily work more efficient and forward-looking.

Maximum availability through precise condition monitoring

Maximum availability through precise condition monitoring

© IFE Aufbereitungstechnik

What can the tool do?

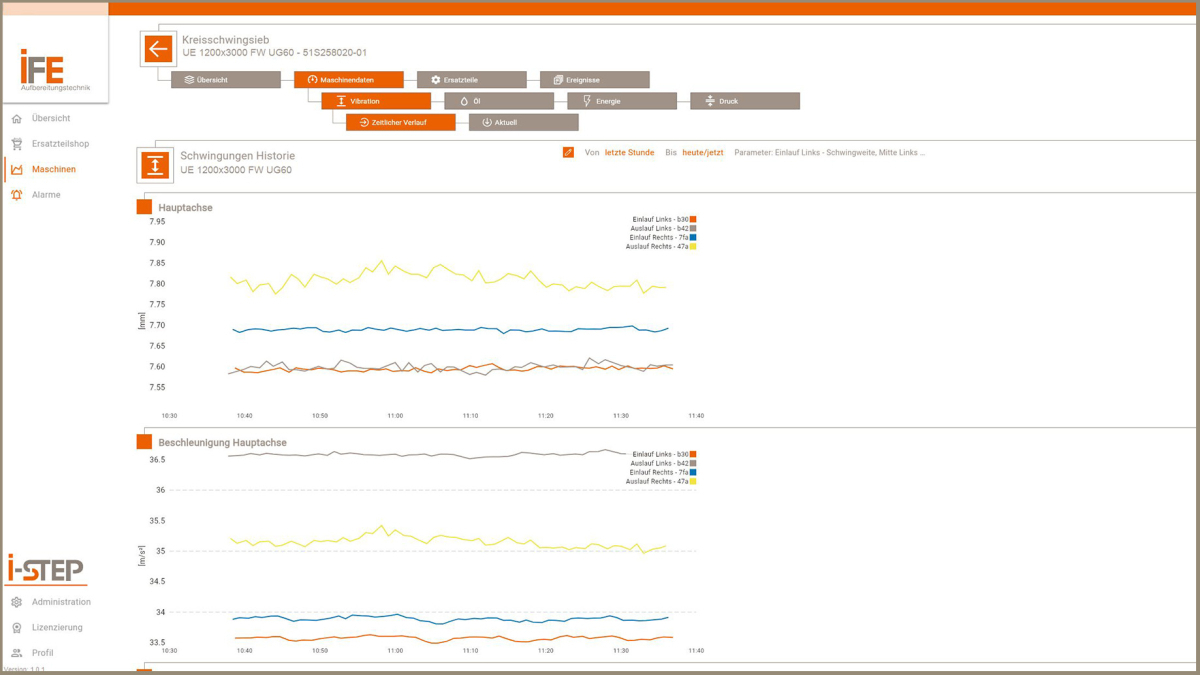

The i-STEP Operator uses sensors from IFE and compatible third-party sensors to continuously collect relevant machine data. This data is automatically transferred to a user-friendly interface, where it is clearly structured and visually presented. It provides operations managers with a comprehensive overview of the condition of their machines – without having to be on site in person. If deviations occur, the recorded telemetry data can be shared directly with IFE.

With the i-STEP Operator, maintenance becomes data-driven rather than intuition-based. Instead of relying on gut feelings or employee assessments, plant managers can make decisions backed by reliable, real-time data. Device-specific maintenance plans can be stored for both IFE and third-party machines. Notifications and alarms provide early warnings of upcoming maintenance tasks, unexpected deviations, and potential malfunctions –ensuring maximum equipment availability and efficiency.

The i-STEP Operator converts meaningful machine data into user-friendly evaluations and reports

The i-STEP Operator converts meaningful machine data into user-friendly evaluations and reports

© IFE Aufbereitungstechnik

The i-STEP Operator is also the central hub for IFE spare parts. By registering an IFE machine, the corresponding spare parts lists are automatically stored. Specific spare parts can be quickly identified and requested using dynamic full-text search. The document center provides further simplification. Original documents (e.g., operating instructions) can be accessed directly there. They are displayed on the platform in an integrated PDF viewer with a download function.

Integration of various sensors

For machine monitoring, sensors from IFE as well as from third-party providers (e.g. via an OPC UA interface) can be integrated. These can also serve as basis for virtual sensors, such as operating hour counters.

The i-STEP Operator provides a reliable source for long-term machine assessment. Based on historical and reliable real-time data, machines can be analyzed over long periods of time. This enables specific condition assessments, makes trends transparent, and allows for data-driven predictive maintenance – a forward-looking maintenance plan.

The i-STEP Base Station offers a practical testing option

The i-STEP Base Station offers a practical testing option

© IFE Aufbereitungstechnik

Free access and flexible expansion options

The i-STEP Operator is available to all IFE customers free of charge in the “Light” version. Customers can simply register using their email address and VAT number. Once registered, users can set up their own machines, customize the dashboard and notifications, and add colleagues as needed. For more advanced requirements, IFE offers additional packages with a wider range of functions, including customized solutions that can be requested directly from the company. Those who would like to test the i-STEP Operator in practice can also book the i-STEP Base Station with wired and mobile Vibrosense sensors for a defined test period.

“With the free starter version, we want to give all customers the opportunity to easily discover the advantages of the i-STEP Operator and gradually integrate the system into their everyday operations,” explains Reinhard Hochstrasser, who is responsible for the i-STEP product line in the after-sales department at IFE.