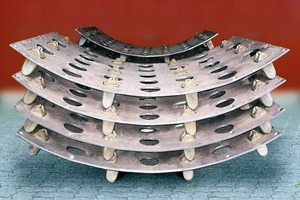

Cost effective solution for moderate wear

Kalenborn now offers a comprehensive array of KALMETALL-HB hard steel as cost-effective solution for moderate wear. The typical KALMETALL-HB material 400 features a hardness equivalent of approx. 400 Brinell. Materials of greater hardness are available if necessary. Among these is, for example, KALMETALL-HB 500 having a hardness equivalent of 500 Brinell. The special hardness and impact resistance of KALMETALL-HB hard steel results from the production method as well as the time-tested alloys chosen for this purpose. The specific material properties are reached by the defined addition of, e.g.,...