Low-noise and wear-resistant

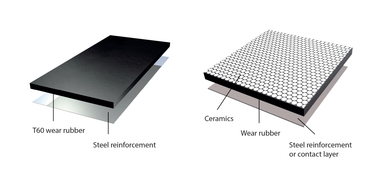

Sandvik supplies wear-resistant rubber linings suitable for all dumper truck bodies and hoppers used in the mineral processing industry (Fig.). Loading surfaces and rear flaps are subject to extreme material wear during loading and unloading. The WT6000 wear-resistant rubber panels and mats absorbe the impact energy by the elastic rubber, protecting the steel body. Moreover the wear protection panels considerably reduce noise levels. Measurements have shown that noise can be reduced by up to 20 db(A) compared to steel linings. With WT6000, Sandvik offers a tailored solution for every...