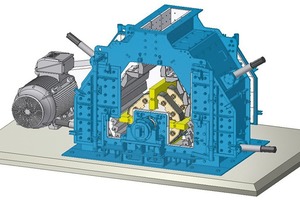

New impact crusher with consistent product quality, high cubicity and reduced downtime and maintenance

Dr. Armin Greune, Head of Standard Machines in the Business Unit Mining Technologies of thyssenkrupp Industrial Solutions: “The variopactor is designed for use in small and mediumsize quarries and meets our customers‘ key requirements – problem-free, cost-efficient production with reduced downtime.“

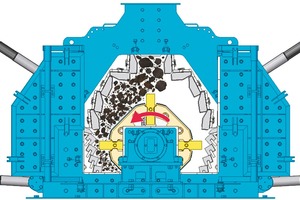

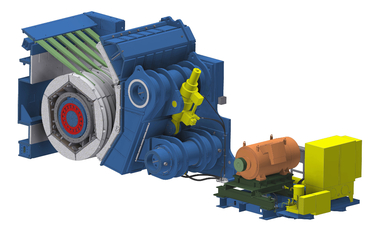

The housing, rotor, and entire crushing chamber of the variopactor are symmetrical, so the rotor can be operated in both directions and the direction of rotation can be changed at any time. Using the rotor in both directions ensures the blow bars always operate with a sharp edge and minimizes the need to replace or turn the blow bar. The variopactor is maintenancefriendly; all wear parts are easily accessible and can be replaced quickly.

During the crushing process, the blow bars are subjected to enormous stresses. For the first time thyssenkrupp is offering the option of Metal Matrix Composite (MMC) blow bars with high-carbide inlays. Depending on application and customer requirements, the matrix material for the MMC blow bars can be made from different steel alloys. The high-carbide inlays are cast into the matrix material in the main wear zone along the edge of the blow bars, where most of the crushing work takes place. These blow bars are a new application for this material, which has been used for years to maximize the service life of hammers for hammer crushers as well as sizer and roll crusher teeth. Compared with traditional high-carbon chromium steel, it also significantly increases the service life of the blow bars.

One of the variopactor‘s key strengths is its modular design. All parameters influencing the product quality, such as rotor speed and apron or grinding path position, can be flexibly adapted to the individual requirements of customers in the minerals industry. With the variopactor‘s hydraulic gap adjustment system, the aprons and grinding paths can be repositioned at the push of a button so the machine can quickly be set up for different product requirements.

Advantages of the new variopactor at a glance:

Production of gravel, chippings and sand with one machine

Crushing of medium-hard to hard rock

Consistent product quality with high cubicity

Increased service life of blow bars thanks to use of Metal Matrix Composite

Good accessibility from both sides and easy-to-fit wear parts

Significantly reduced downtime for maintenance

Modular design: Use of different rotors, aprons and grinding paths

Simple adjustment of aprons and grinding paths at push of button

Easy to integrate into existing equipment