Optimization by computer - Optimization of Mineral Processing Plants

with Simulation Software “NIAflow”

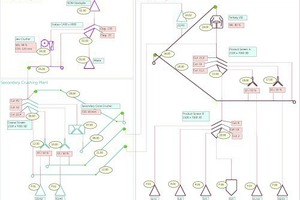

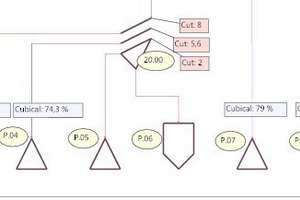

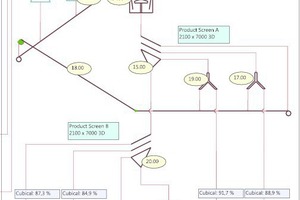

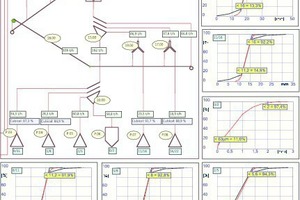

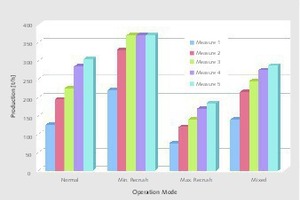

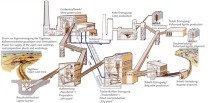

Summary: Years can pass from the first feasibility study through the project phase to the start-up of a mineral processing plant. During this time the originally defined technical and commercial framework could have changed significantly. It can be difficult to meet all defined parameters when putting a plant into operation. But even in the case of a successful startup the market can have changed. For the optimization of entire processing plants a simulation of the plant using software products like NIAflow® is advisable. During this simulation the process of the plant is modelled and evaluated in the software. Every piece of equipment is represented by an object in NIAflow®, the material flow through these objects is visualized and calculated.

1 Introduction

Years can pass from the first feasibility study through the project phase to the start-up of a mineral processing plant. During this time the originally defined technical and commercial framework could have changed significantly. It can be difficult to meet all defined parameters when putting a plant into operation. But even in the case of a successful startup the market can have changed. The defined products may not be in demand as before and the return of investment may be in danger. In general, any processing plant needs to be adjusted or optimized to varying situations.

Typic...