SBM V8 vertical impact crusher at Moosleitner

With around 600 000 t of gravel raw materials and a further 120 000 t of certified recycled building materials, Plant 2 in Saaldorf is the largest operation of the German-Austrian Moosleitner Group. Two gravel pits, three concrete plants, and other quarries, recycling, and landfill sites operated independently or with partners in both countries are part of the raw materials, building materials, and environmental division. With a total of over 200 employees, the long-established family business also operates across borders in the fields of earthworks, civil engineering, road construction, and demolition.

Since the beginning of 2023, road construction materials in Saaldorf have been processed by a SBM REMAX 400 mobile impact crusher (0/400 mm into certified 0/16 mm, 0/22 mm, 0/32 mm, 0/63 mm). The aggregates for two of the company’s own concrete plants and other concrete plants in the region are supplied by a stationary 300 t/h gravel washing plant. The multi-stage screening plant produces high-quality grain sizes of 0/4 mm, 4/8 mm, 8/16 mm, and 16/32 mm from 0/100 mm feed material, with an average annual output of around 400 000 t. Since 2010, some of the coarse 32/70 mm grain and other surplus material has been processed into chippings and crushed sand, primarily for asphalt production, by an 80 t/h cone crusher located directly next to the gravel washing plant.

Flexible value creation

Due to the natural grain spectrum and the current market situation, Saaldorf has surplus quantities of 10 000 to 20 000 t/a, particularly in the 4/8 mm and 16/32 mm grain sizes. In contrast, as in many regions, there is high demand for high-quality 0/4 mm concrete sand.

Since the end of 2023, an SBM V8 vertical impact crusher has been closing this gap: specially developed for efficient sand production, the compact crusher was integrated into the existing crushing station with feed hopper, feed conveyor, and double-deck screen. With an hourly output of 60 to 70 t, the SBM V8 now processes excess 4/8 mm or 16/32 mm grain sizes into high-quality 0/4 mm crushed sand, which, with its distinctive cubic grain shape and precisely controllable grading curve, can be directly mixed with washed 0/4 mm concrete sand without further post-treatment. Depending on the results of the accompanying laboratory tests, the addition is between 10 and 20 %, whereby the targeted control of the properties of the crushed grain size also allows the quality of the 0/4 mm delivery grain size to be optimized by correcting the sieve curve.

Decision for the “sand machine”

“Our solution with the SBM V8 vertical impact crusher has fully met our expectations,” explains senior manager Matthias Moosleitner, who runs the Moosleitner Group together with his wife Martina and son Mathias. The evaluation phase lasted a good six months and included on-site assessments of various oversize solutions that had already been implemented. Different tertiary crushers were evaluated not only in terms of their crushing characteristics, but also with a focus on the most economical technical integration into the existing gravel washing plant.

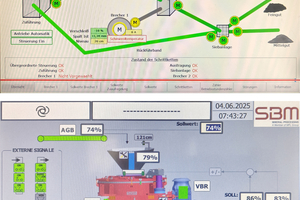

The goal was to create an end product that was as compatible as possible with the washed Saaldorf concrete sand in terms of grain shape and distribution. The decision was ultimately made in favor of the SBM V8 vertical impact crusher: Like the larger V crushers with hourly outputs of up to 160 t/h, it was specially developed for sand production and the cubing of poorly shaped fine grains. With vertical feeding (feed sizes 35/40 mm), the patented SBM feed control and the electric drive with frequency converter-controlled rotor speed as the key control parameter, SBM V crushers can be easily integrated into existing plants. In the standard design, crushing takes place in the autogenous material cushion or “good bed” thanks to the high energy input of the specially developed high-speed rotors. The SBM feed control with level monitoring at the material hopper minimizes the suction effect even at constantly high rotor speeds, thereby maintaining the material cushion and ensuring consistent quality, low wear costs, and low dust emissions under full or partial load.

As an easily movable unit in a steel frame with a surrounding maintenance platform, the SBM V8 vertical impact crusher weighs around 7.5 tons and was therefore easy to integrate into the existing plant technology in Saaldorf. It is fed from the wheel loader via a swivel belt, and the crushed material is transported to the double-deck screen with oversize material return to the feed hopper and wide conveyor belts for the final grain sizes of 5/8 mm gravel and 0/4 mm crushed sand.

The calculation works out

After around 200 operating hours, Matthias Moosleitner gives a positive assessment: “We were able to integrate the SBM V8 into our crushing station without any problems. It delivers consistently high quality, both in terms of grain shape and the grading curve, which is crucial for the controlled addition to our washed concrete sand.” The production output is also right: “At 60 to 70 t/h, it easily matches the sand output of our washing plant, whereby the self-sufficient operation naturally allows us full flexibility in processing any excess grain sizes.”

Operations manager Peter Gastberger also highlights the advantages of the SBM vertical impact crusher: “With the V8, we can precisely adjust the properties of the crushed 0/4 mm material to the washed grain size. We are currently working with three presets in the crusher control system that take into account the usual fluctuations in the washed sand.” The SBM V8 also impresses in terms of operation and maintenance: “Thanks to the feed control, the crusher operates quietly, with low vibration and virtually no dust, even under full load. Especially in direct comparison with our cone crusher, wear is extremely low, which minimizes our maintenance costs and, together with the electric drive concept, significantly increases the availability of the V8.” Take winter operation, for example: While the cone crusher, with its approximately 300 l of gear and hydraulic oil, requires a considerable warm-up time at low temperatures, the SBM V8, with its grease lubrication and just 10 l of hydraulic volume for gap adjustment, is ready for operation in no time at all.